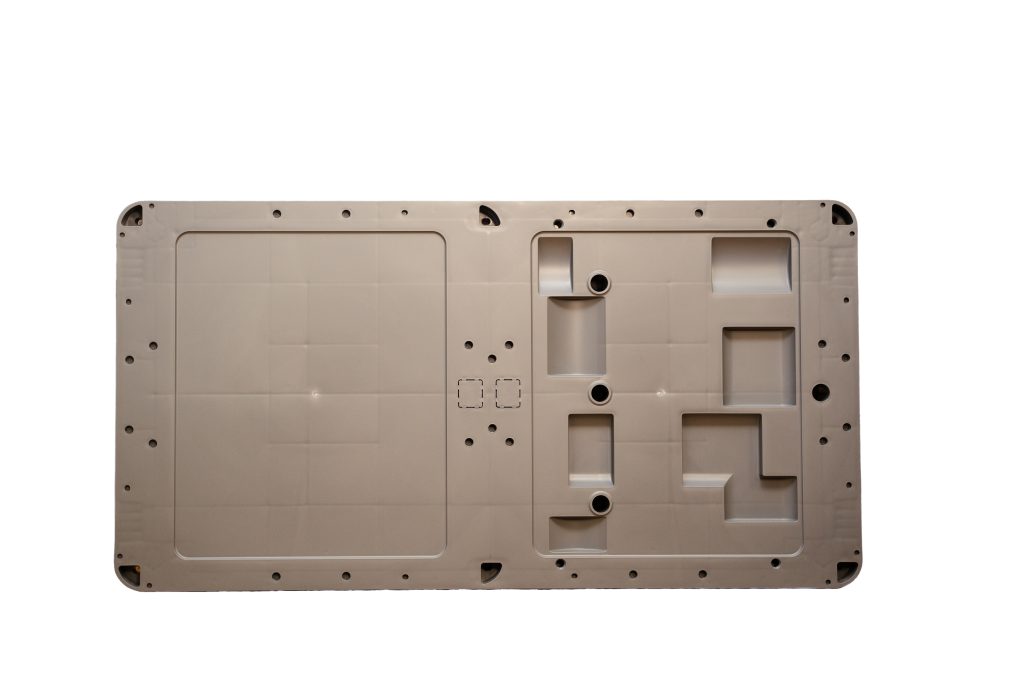

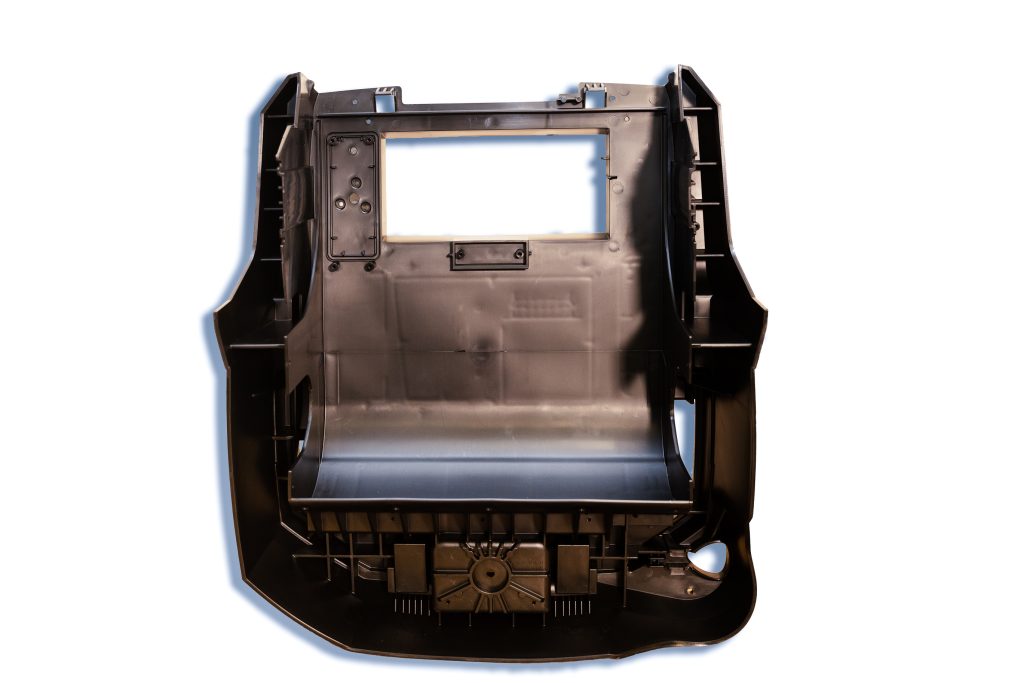

Parts weighing ≤ 8000 g

We have a wider range of equipment that allows us to design and manufacture moulds for parts weighing from 0.2 to 8000 g. This means that you will be able to produce a wider range of products in one place.

Moulding of single component parts

Production efficiency is achieved by working around the clock and determining the number of moulding slots. We produce from an unlimited range of raw materials: LDPE, HDPE, PP, PVC, PPT20, PPGF30, PS, ABS, PC, SAN, ASA, POM, PA6, PA66, PA66GF30, TPE, TPU and others. In addition, we use well-known, high-quality moulding equipment (KRAUSS MAFFEI, ARBURG, DEMAG).

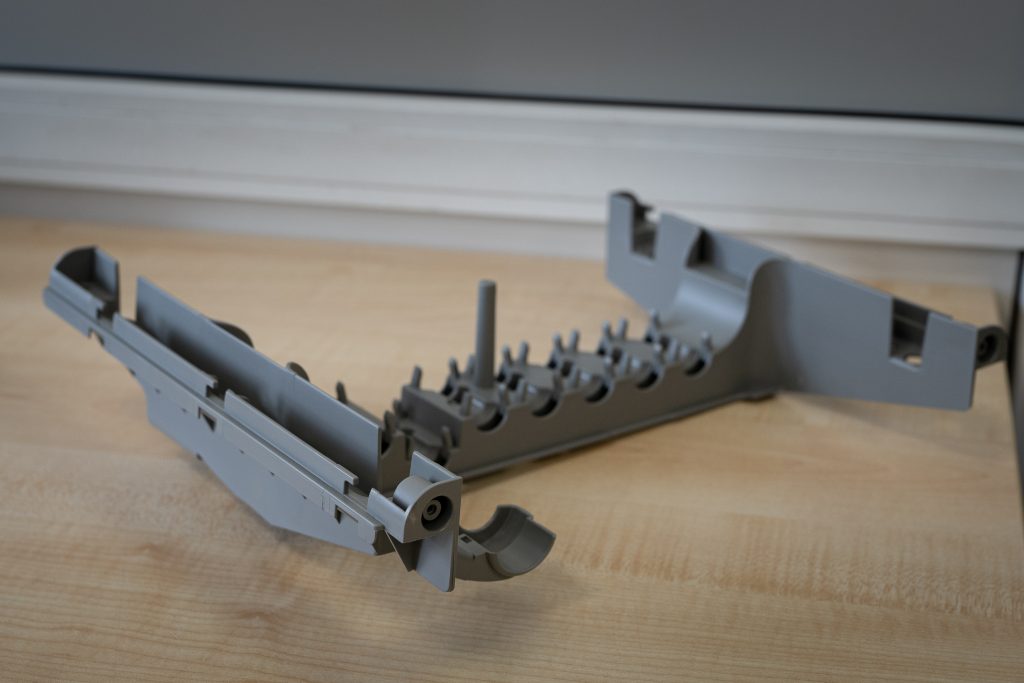

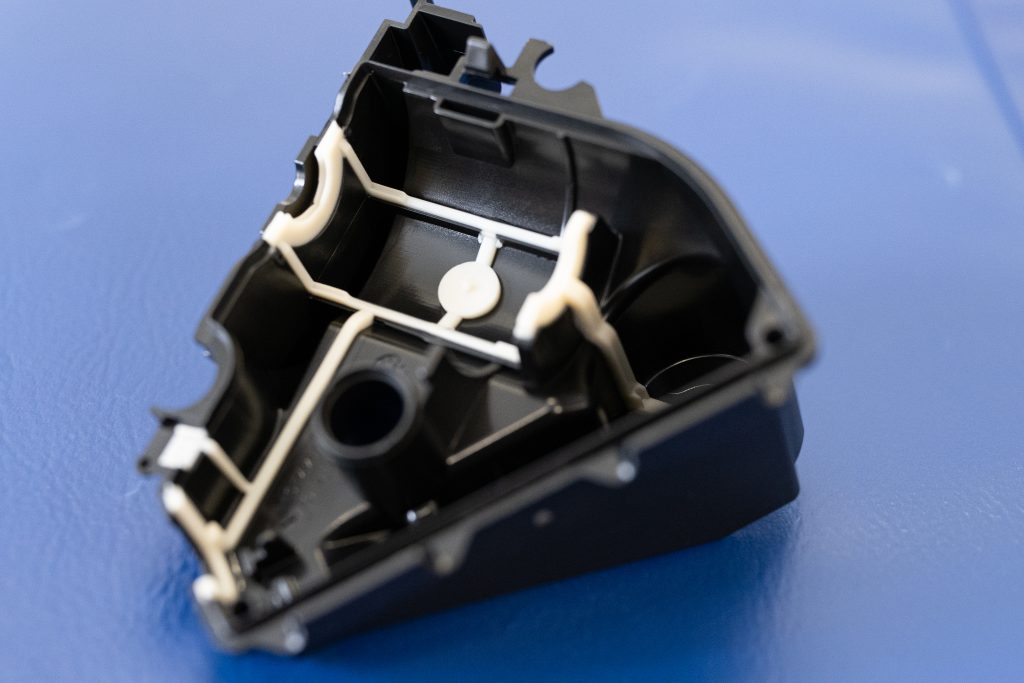

Moulding of two-component parts

We apply two-component moulding technology for the production of complex and higher quality parts. In this way, we combine different materials with different mechanical properties in one product. The weight of the parts ranges from 0.5 to 600 g. We use well-kwon KRAUSS MAFFEI and ARBURG equipment.

Moulding of three-component parts

We can also mould three-component parts while combining different materials into a single mould that can meet very complex requirements.

Moulding of thick-walled parts

By applying the multi-layer technology, we can mould parts up to 8000 g. The flawless appearance of the products is achieved by forming the parts from internal and external layers. We use high-quality materials for the outside, where the visual appearance of the product is important. While the core can be made to be more economical, as we use additives that, when mixed into the plastics, make the internal structure honeycombed. As a result, the product becomes lighter.

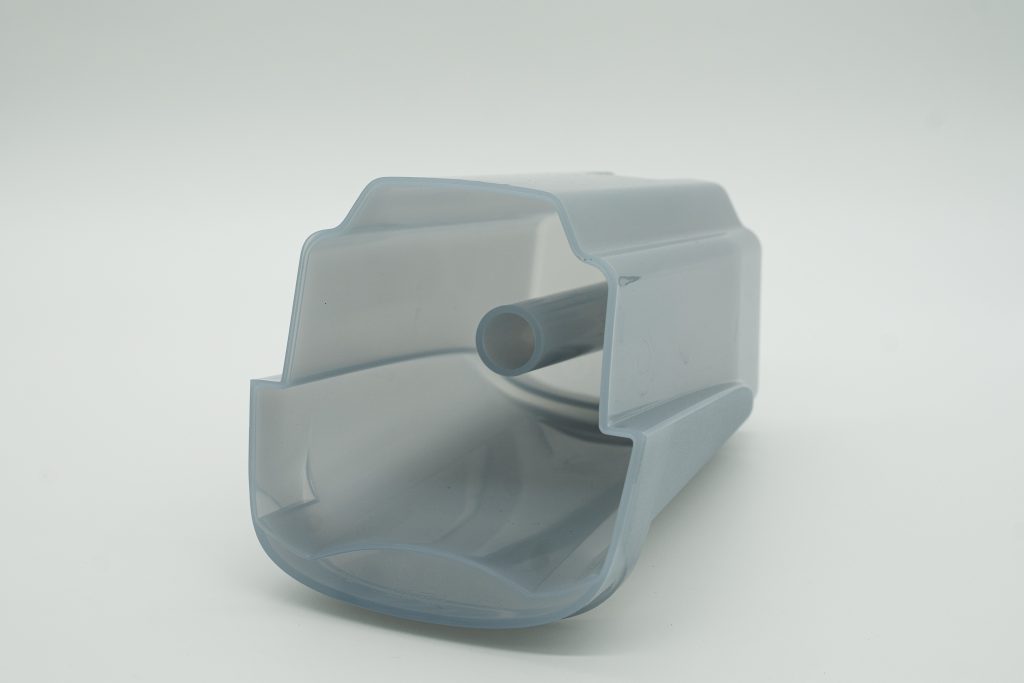

Moulding of transparent parts

Our clients, who need products with a higher light transmission, can expect the highest quality. We have all the necessary competencies and valuable experience in the production of transparent parts and we work together with the world’s best suppliers of raw materials. We usually use such materials as SAN, PS, PMMA, PC for moulding transparent parts.

Moulding of parts with high surface gloss

We manufacture the moulds ourselves, so we can polish their surface to the required gloss.

Moulding of hollow parts

We also produce hollow parts. During the process of such moulding, we additionally inject compressed nitrogen gas, which, under pressure, presses the heated plastic against the walls of the mould, causing the part to become hollow.

Casting of metal or other liners

If you are looking for a more economical and faster assembly of the final product, we can join the individual parts by casting. In this way, we will make a durable and aesthetic part, and you will avoid the process of assembly and the costs associated with it.

Plastic colouring during the moulding process

Create your own unique design with the help of coloured mouldings. When dyes are applied during the moulding process, they move together with the part, making the product more resistant to splitting, cracking and chipping.

Moulding of parts from recycled materials

We sort, crush and re-granulate the products of the moulding process that are unsuitable for their initial use. Our employees have the knowledge and experience necessary to reuse such raw materials while moulding parts without compromising the quality of the final product.