Surface processing is the last stage of the production. It gives the product not only an aesthetic appearance, but also reduces surface roughness, increases chemical and electrical resistance. It also protects parts against external factors such as corrosion.

Painting parts with liquid paints

We paint plastic and metal parts of various sizes and shapes. We prepare the paints ourselves and have an unlimited choice of colours.

Powder coating

Powder coating is used when a product has to be resistant to outdoor conditions, chemicals and ultraviolet rays. This type of coating gives the surface an exceptional structure and is characterised by its high-quality and impeccable appearance.

Zinc coating

Galvanization is applied when it is necessary to increase the anti-corrosion properties of the product or to obtain a specific image. We accept both single and serial production orders.

Anodizing of aluminium surfaces

Galvanic anodizing technology is applied for finishing aluminium parts.

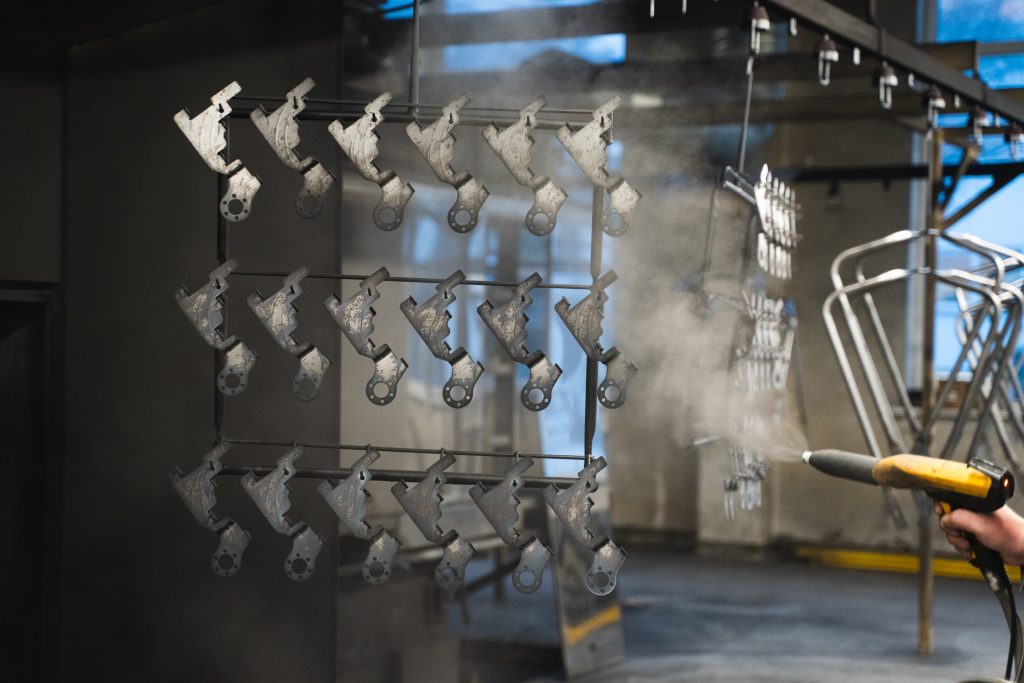

Preparation of parts and creation of their structure by sandblasting

Sandblasting is applied to obtain an aesthetic structure of the metal surface or prepare aluminium and ferrous metal for painting.

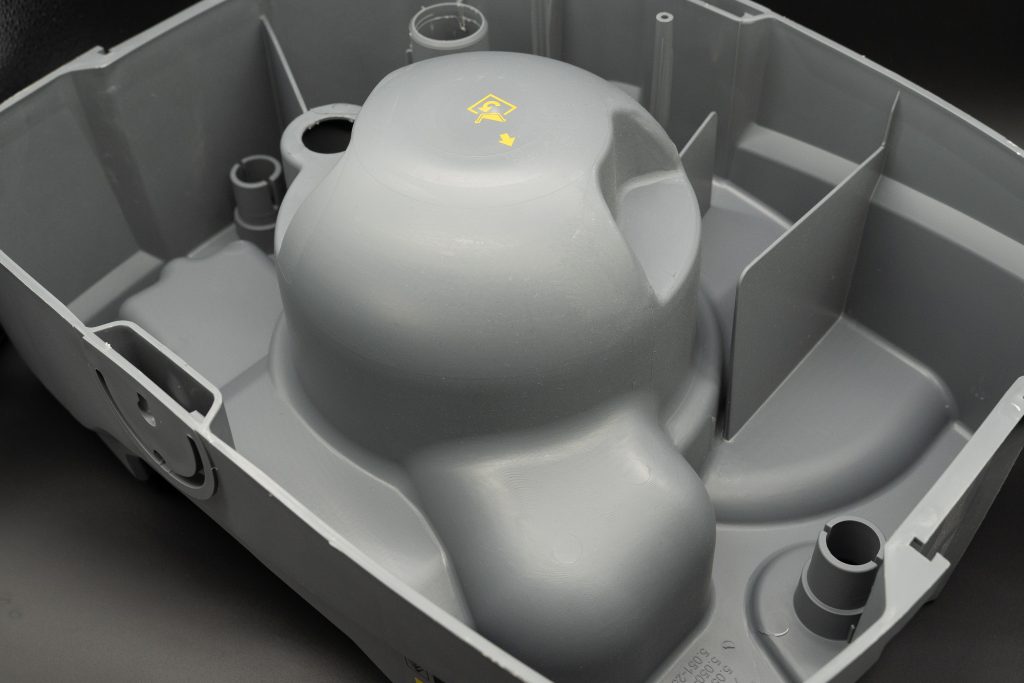

Tampography

It is an intaglio printing process that allows us to transfer coloured inscriptions to the surfaces of various parts during their manufacturing process. We make our own printing forms and prepare the paint.

Screen printing

For larger products and upon the request of a client, we can print inscriptions by applying screen printing technology. We use our own stencils and prepare the paint.