Our company has been making stamps and moulds for plastic and aluminium for over 50 years. We can design and manufacture tools and equipment for a wide range of industries, from automotive to household. In addition, we provide non-standard solutions.

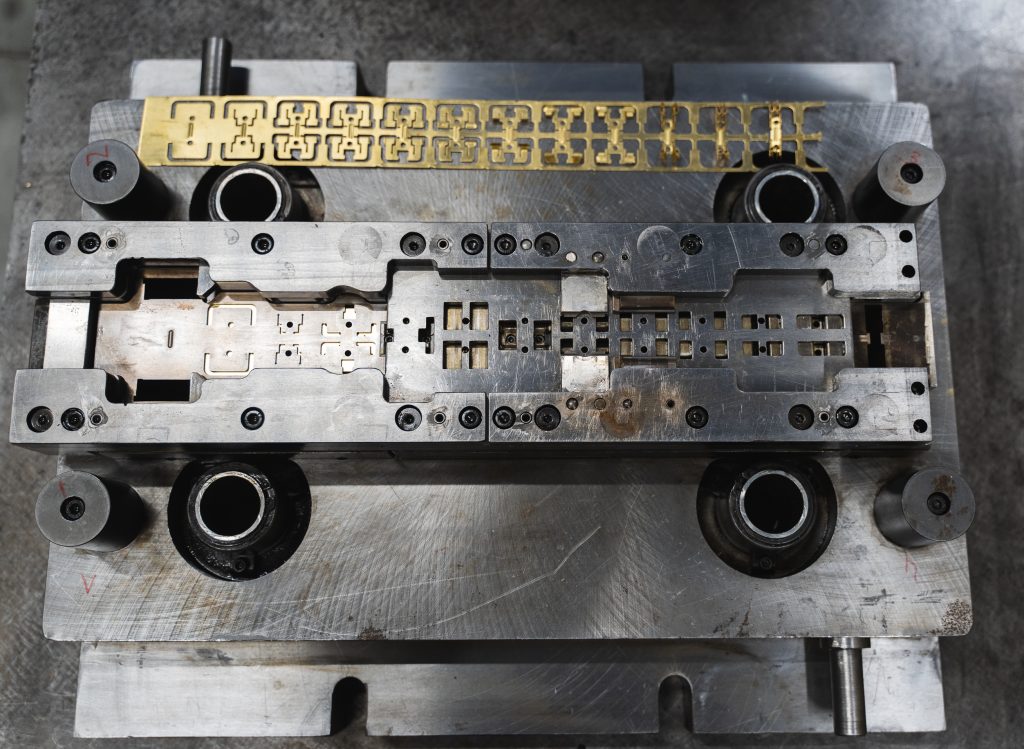

Stamps for metal parts

We design and manufacture contour cutting, bending and combined (step) stamps for larger serial production. We use modern Swiss and German equipment brands (Hermle, Roders, ZK, Agie Charmilles). The maximum dimensions of the stamp are 1000×800 mm.

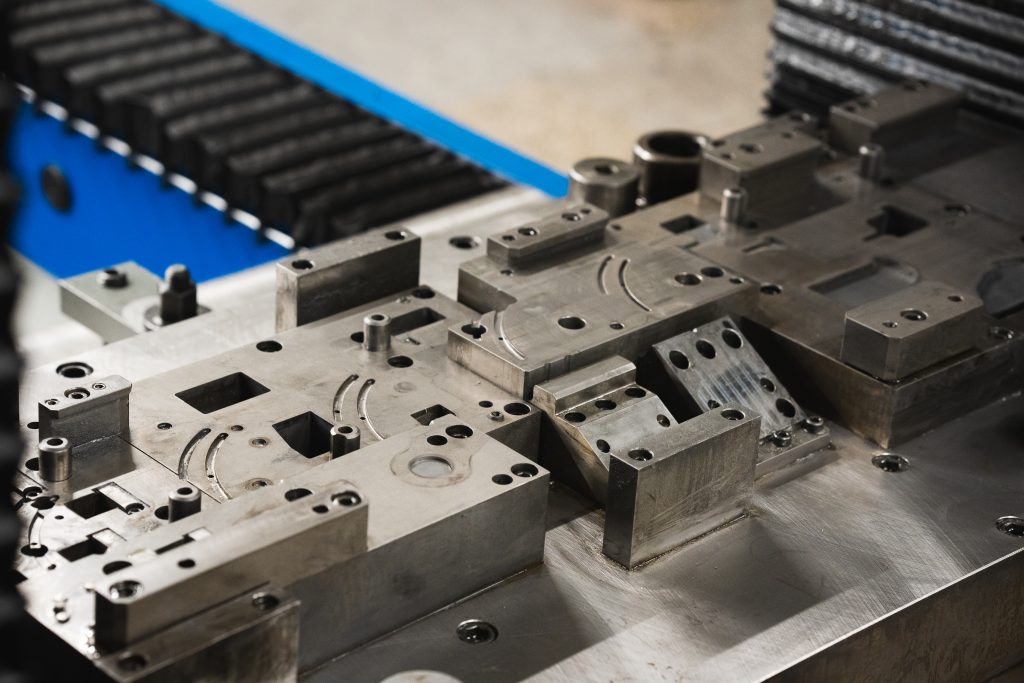

Moulds for plastic parts

For 40 years, we have been manufacturing complex, single or multi-component, hot or cold runner moulds with moving mechanisms and replaceable inserts. Maximum equipment size: 6 tons, 1000×800 mm. Together with our partners, we can produce up to 140 moulds per year.

Moulds for casting aluminium parts

Aluminium and zinc mould making is our daily task while working in the automotive, industrial and home appliance markets. We produce complex shapes for thin-walled parts. The maximum product size is 1000×800 mm. Our experience and technology allow us to ensure detail accuracy down to approximately 0.01 mm.

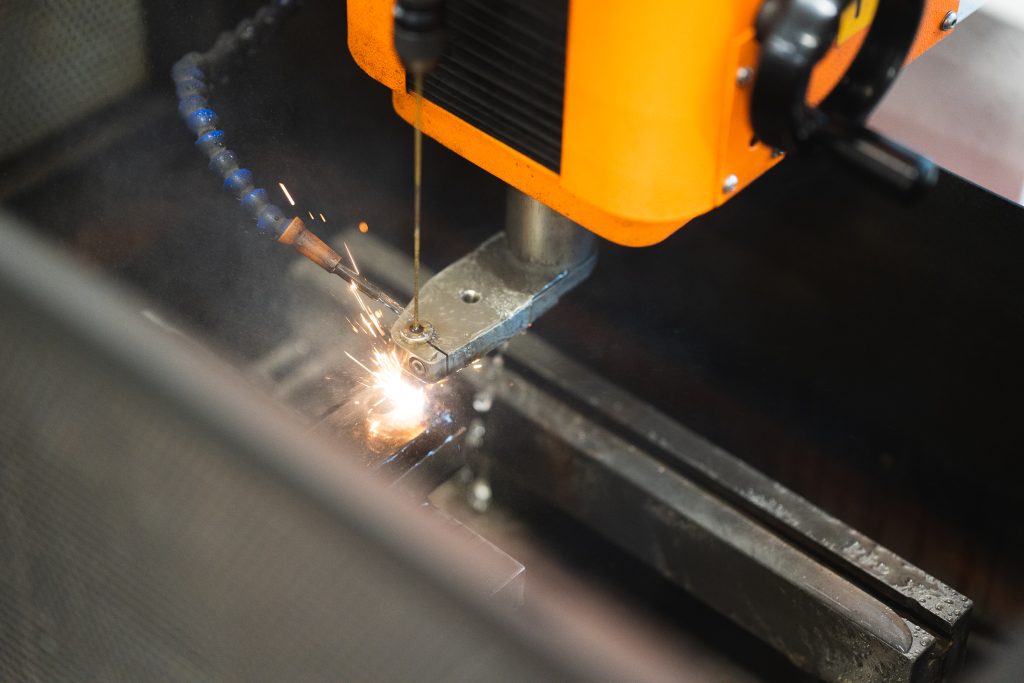

Other services provided

Our advantage is the provision of complex services. We design, perform Moldflow analysis, carry out the milling, hardening, wire cutting, volumetric erosion (die sinking EDM) and EDM drilling (Ø 0.3–3 mm). We also repair moulds and manufacture equipment for the automation of the moulding processes.